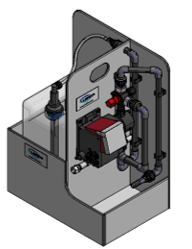

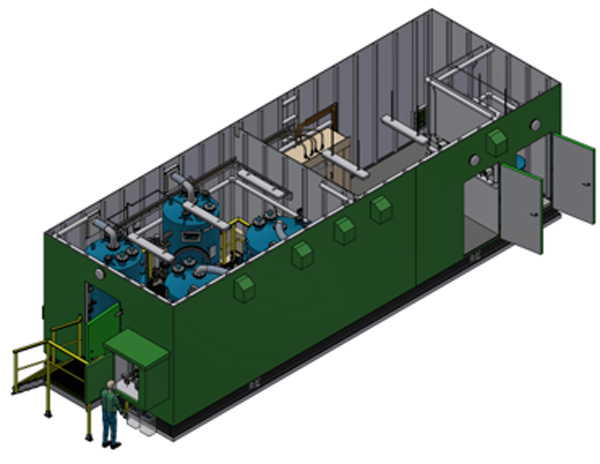

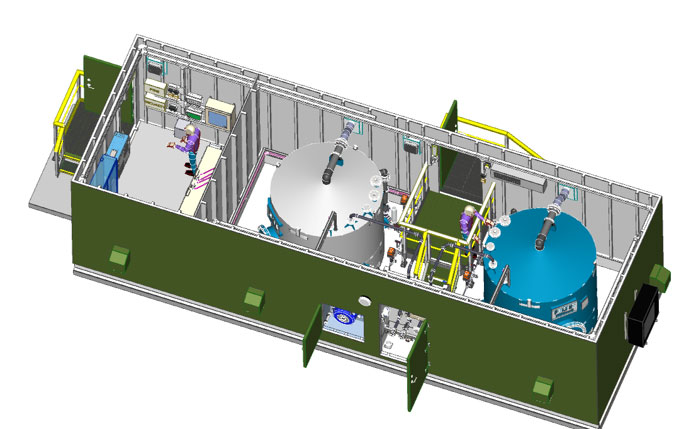

At LEADA Engineering Ltd, we’re always looking for ways to improve the resilience, flexibility, and sustainability of our dosing systems. Last week, director Ben Paxman travelled to meet with the Mining Remediation Authority to demonstrate the latest addition to our dosing fleet, a fully enclosed, self-powered, remote access and control dosing system.

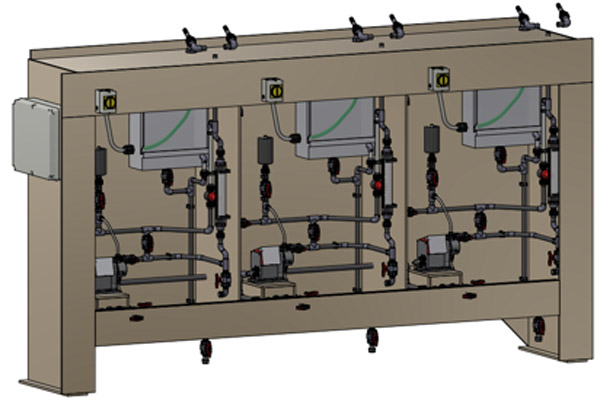

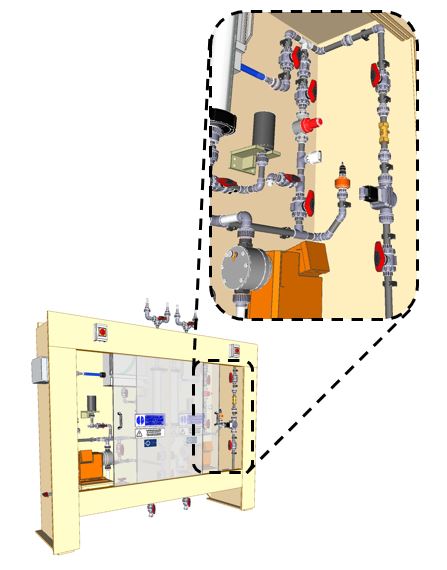

This visit was an opportunity not only to showcase the new unit’s capabilities but also to highlight the significant upgrades we’ve made to its power systems, programmable logic controller (PLC), and operator interfaces, ensuring it remains one of the most advanced systems of its kind on the market.

Why This System Matters

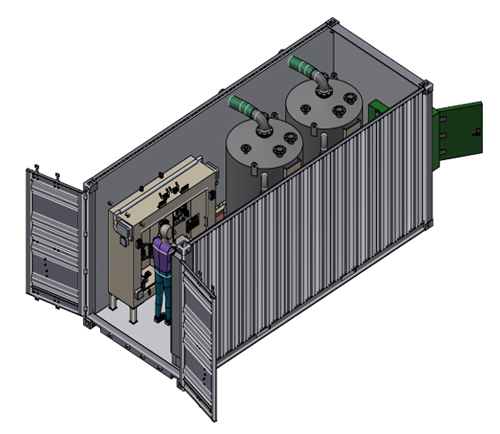

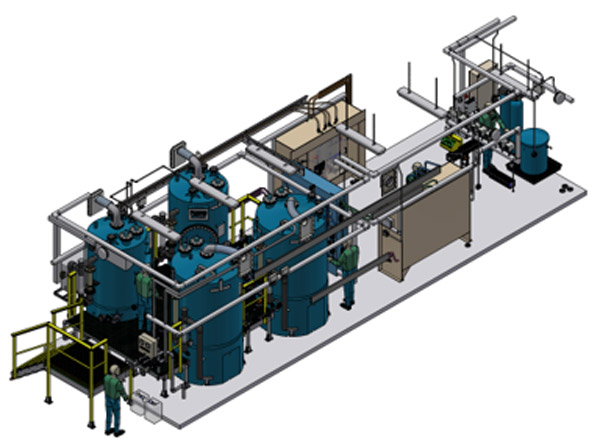

Mining and industrial sites often operate in challenging, remote, or unpredictable environments — and when dosing systems are required for water treatment, chemical remediation, or emergency response, reliability and rapid deployment are absolutely critical.

Our latest dosing system addresses these needs head-on:

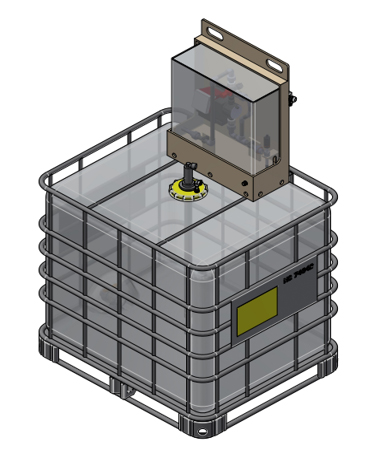

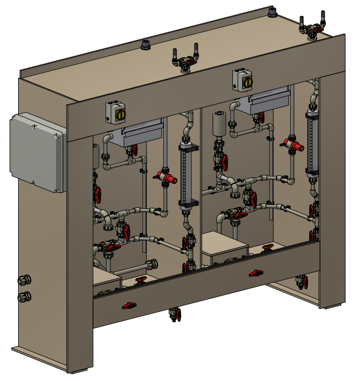

• Fully enclosed and weatherproof, ensuring safe operation in all conditions.

• Self-powered and completely off-grid, removing the need for mains electricity or backup generators.

• Remote access and control, allowing operators to monitor and adjust dosing parameters without being on-site.

• Compatible with a wide range of chemicals, thanks to the flexibility of wet components in our fleet.

• Deployable within hours, making it ideal for emergency environmental response situations.

Supporting Sustainability and Innovation

This system isn’t just about performance — it’s about supporting our clients in achieving their carbon reduction and sustainability targets. By operating off-grid and integrating the latest control technologies, we help reduce emissions, minimise energy consumption, and enable smarter, more efficient environmental management.

For organisations committed to carbon neutrality and adopting innovative technologies, LEADA Engineering offers a proven, practical solution.

Find Out More

If you’d like to learn more about how LEADA Engineering can support your site operations or emergency response planning, we’d be happy to discuss your requirements.

Get in touch via our enquiry page: https://lnkd.in/dVhruhJs