Product Database - Chemical Dosing

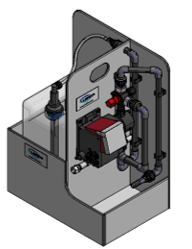

- 25ltr carboy dosing

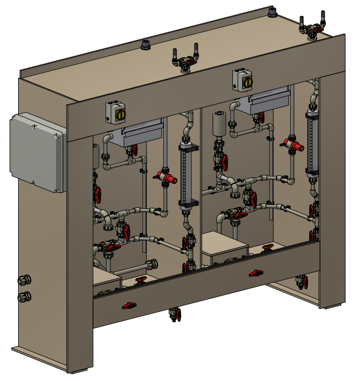

- Dilution systems

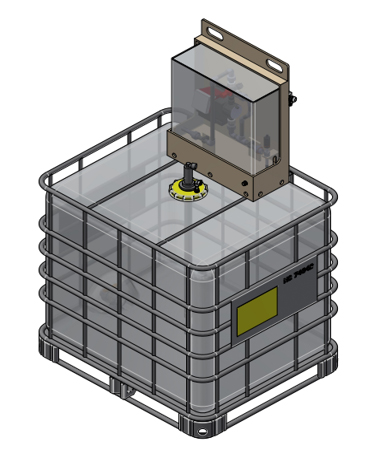

- 1,000ltr IBC dosing

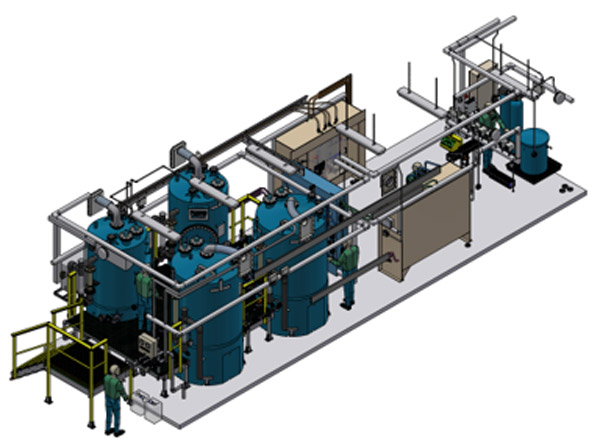

- 1,000ltr Mobile Trailers

- 2,200ltr Mobile Trailers

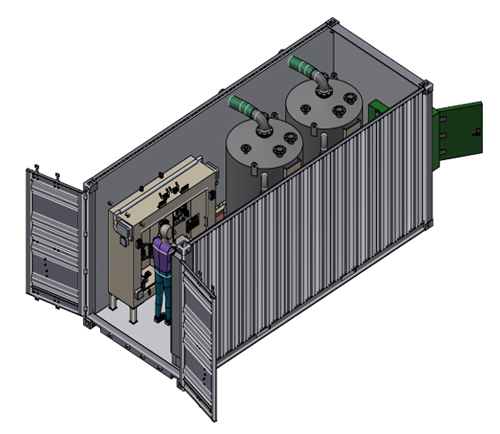

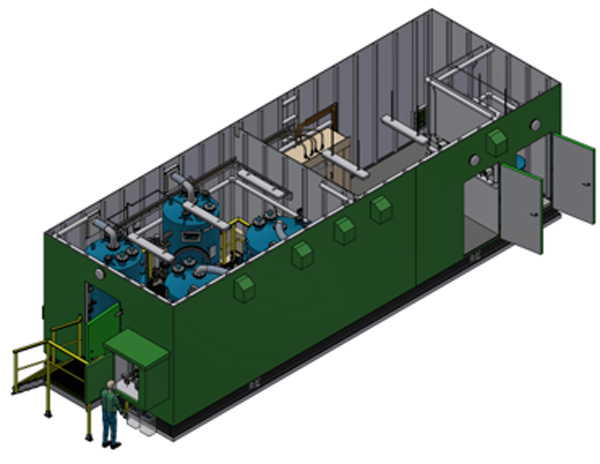

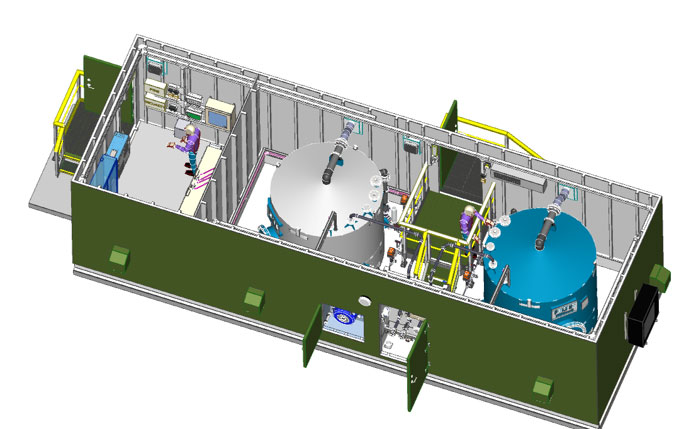

- 4,000ltr Containerised Systems

- Bulk Storage and automated transfer systems

- Overflow Water traps

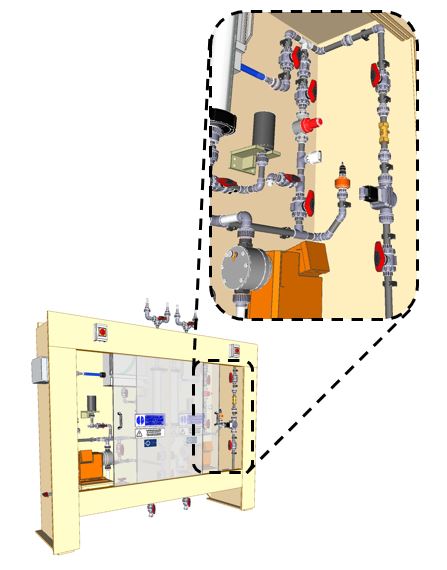

- POA Enclosures

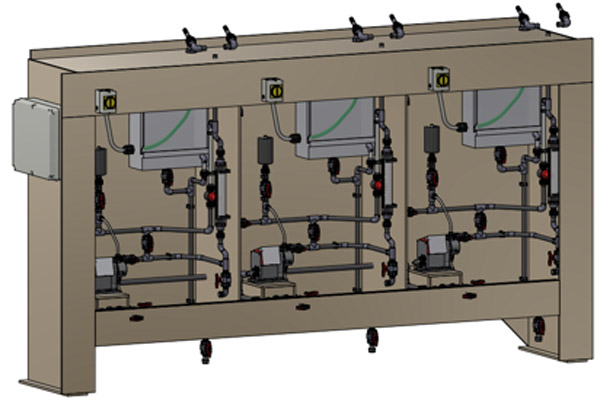

- Carrier Water Injection Enclosures

- POA Splash screens

- Dosing pump covers and manifolds

- URS, FDS Development, Software Design and Hardware Fabrication and build – HMI and screen design and development – bespoke to our clients needs.

- Compact control panels

- Double Bulk Tank Fill Panel

- Single Bulk Tank Fill Panel

- GRP enclosure systems

- Hose reel, interlock and alarm options

- UPS Enclosures to meet full system needs

- Fibre Optic Marshalling Enclosures

- Systems Integration

- Fibre & Ethernet Network Investigations

- Full fabrication and testing off-site

- Bespoke on-site erection

- Offsite fabrication and delivery

- Chlorine, Turbidity, Colour, Manganese, Aluminium, Dissolved Oxygen, H2S and pH