Strongford Storm Generator

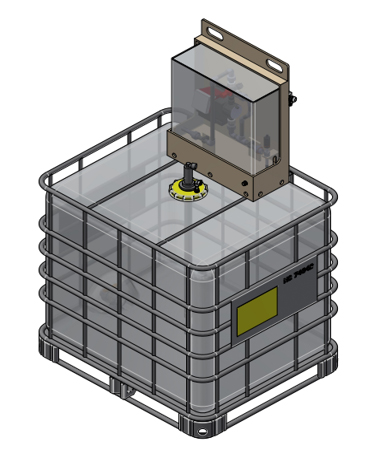

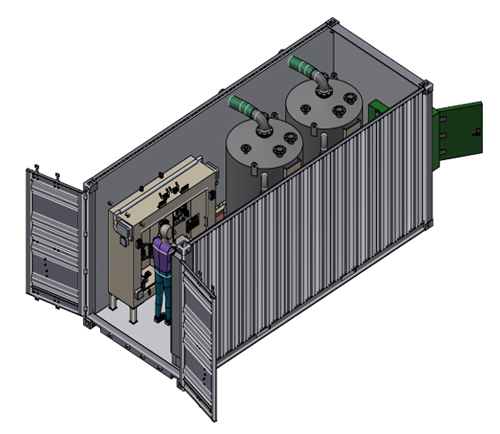

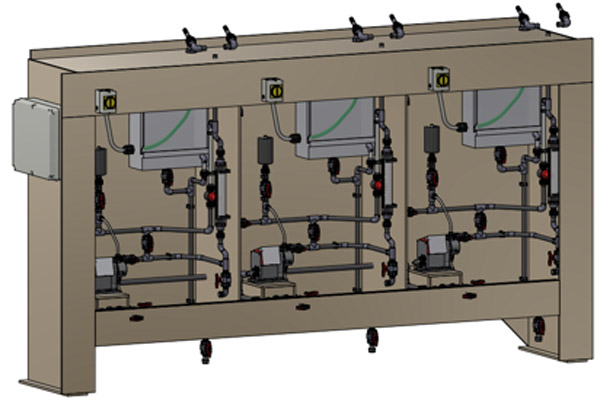

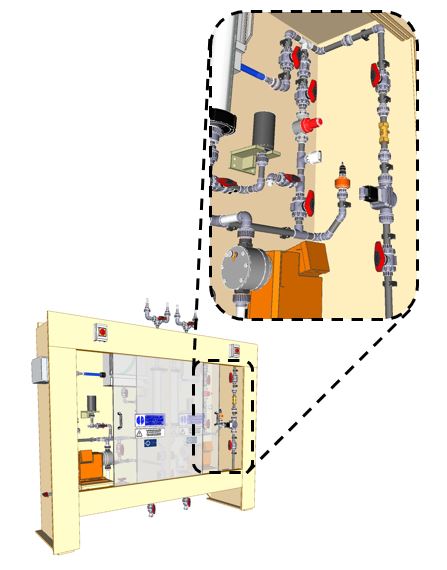

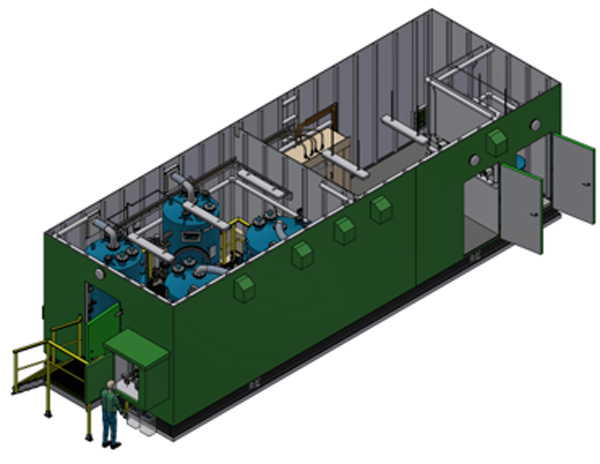

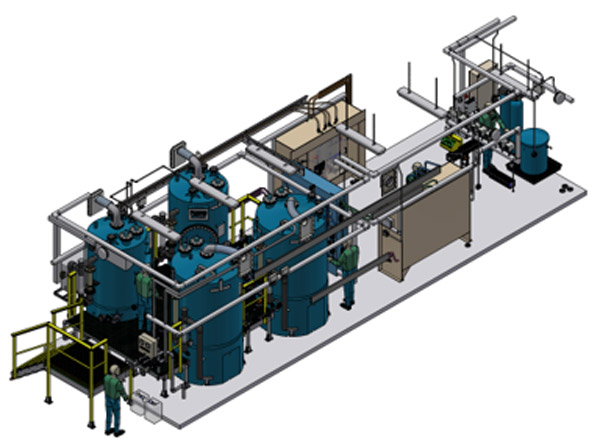

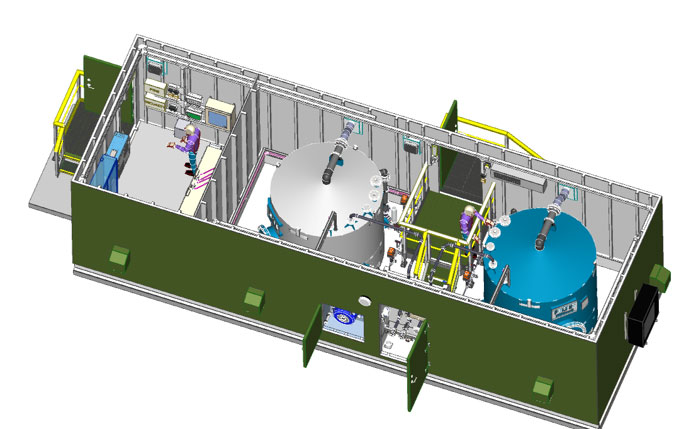

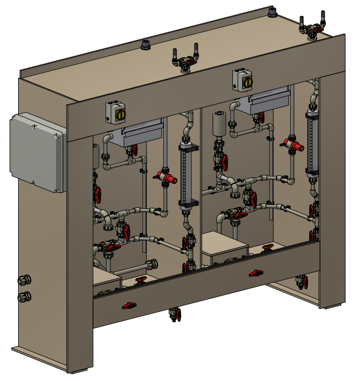

LEADA are engaged through JN Bentley to support Severn Trent Water to design, manufacture and install a Storm Generator test facility at Strongford WwTW. The LEADA team were brought into the project in November 2024, to complete the design, manufacture and installation of the following; The client brief and project driver is for test results to […]

We are recruiting!

Following continued success with our customers and a significant customer return in additional workload, we are actively seeing skilled and motivated individuals to join our team in a variety of positions. If you are contemplating a career change or looking for new opportunities, LEADA could be the ideal next step in your professional journey. At […]

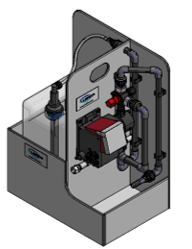

Otley STW – Our Newest Site

LEADA have recently started a new project working with Yorkshire Water Services, to upgrade their STW at Otley in Wharfedale, West Yorkshire. The initial stage of the project includes site-wide electrical, ducting, and ICA investigation work. Once design work has been completed by LEADA, The main body of work on this project will include: Site […]

Our Latest Recruit! Welcome Darrel

Darrel is the latest recruit to have joined our LEADA team. Darrel is a qualified mechanical engineer and electrically qualified, with over 20 years of expertise in water, wastewater, and mine water treatment. He is an experienced project engineer and MEICA Project Manager having worked on projects for most of the UK Water Companies. Projects […]